What is a robotic claw?

A mechanical claw is one of the simplest types of grippers. They are very popular among hobbyists, who are attracted by the simple design and functionality of these clamp types. Typically, a robotic claw (sometimes referred to as a "robotic claw gripper") consists of two claws (also called "jaws") that come together on opposite sides of an object to grasp it. In this article, we will use the term "claw" in its broadest sense; that is, it refers to any type of gripper, including fingers or jaws, that grabs items by closing around the outside of the object. These fingers can be either hard or soft, and soft grippers have many uses in food production and handling delicate objects. TOYO robots support a variety of end-effectors, including claw-type grippers.

How are robotic claws used?

Based on this simple design, roboticists have found multiple uses for robotic claws. Robotic claws are popular end-effectors in manufacturing environments; for example, they can be used to perform robotic arm applications such as assembly, pick-and-place, and packaging and palletizing. Robotic claws can also be seen in space; NASA's InSight mission used a robotic claw arm to place instruments on the Martian surface. Marine researchers even use robotic claws for underwater research on jellyfish.

How do mechanical claws work?

Mechanical claws are typically used to grip/clamp items in manufacturing environments. The two most common types of claws and fixtures used are mechanical and hydraulic. Hydraulic clamping/gripping systems are best suited for high-volume applications and those that must maintain critical tolerances. Using electric pumps and digital pressure switches, hydraulic claws can provide approximately 1% accuracy in clamping force.

Mechanical clamping and claw systems are ideal for small-batch production and situations where wide tolerances are acceptable. Mechanical systems are usually adjusted manually with a wrench, resulting in approximately 10% accuracy in clamping force. Mechanical claws and fixtures are cheaper than their hydraulic counterparts but are also more time-consuming to operate. They are often used in extreme manufacturing environments, such as during high-temperature operations where hydraulic systems are unsafe to use.

Mechanical claws use various methods to close their jaws. For example, in some designs, the jaws close when the central piston is lifted. In other mechanical claw designs, electromagnets are used to clamp the jaws together. The principle is always the same: the fixture uses the jaws to grasp objects.

Many claw-like end effectors are found on collaborative robots, ranging from soft grippers to 2-finger and 3-finger fixtures. These "robot claws" offer a level of intelligence and autonomy far beyond the capabilities of mechanical claws. For instance, robot claws (or robot grippers) can provide useful feedback to your collaborative robots and PLCs. This data can then be used to fine-tune your manufacturing processes. Collaborative robot grippers are also smaller and more precise than mechanical claws.

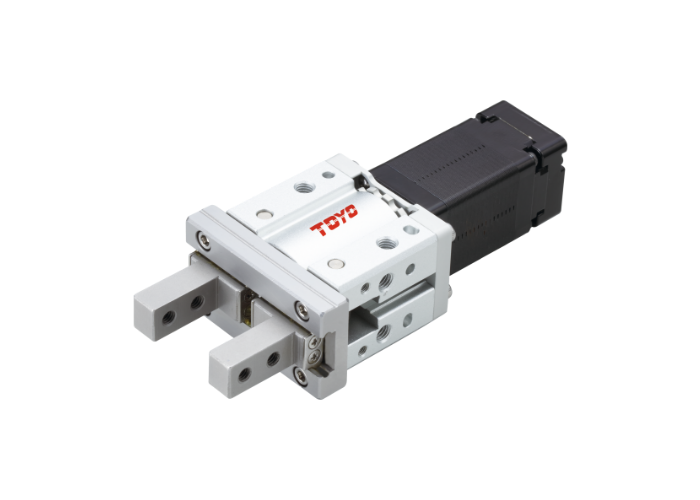

Let's take a look at some claw-like and clamping robots provided by TOYO.