What is an air gripper, and how does it work?

Also known as a pneumatic gripper, an air gripper uses pressure from a compressed air supply system to provide the power needed to move an internal piston, thereby opening and closing the pneumatic gripper fingers (or "jaws") of the gripper.

Since compressed air is already available in most manufacturing facilities, deploying pneumatic grippers is both simple and cost-effective. One of the main advantages of pneumatic grippers is that they provide a large amount of gripping force in a small, lightweight, and low-cost package. For manufacturing facilities where space is at a premium, pneumatic grippers are an economical and ergonomic choice. They are also easy to maintain – once your pneumatic

夹具工作,它可以提供数百万次循环而无需维护。

What is an electric gripper, and how does it work?

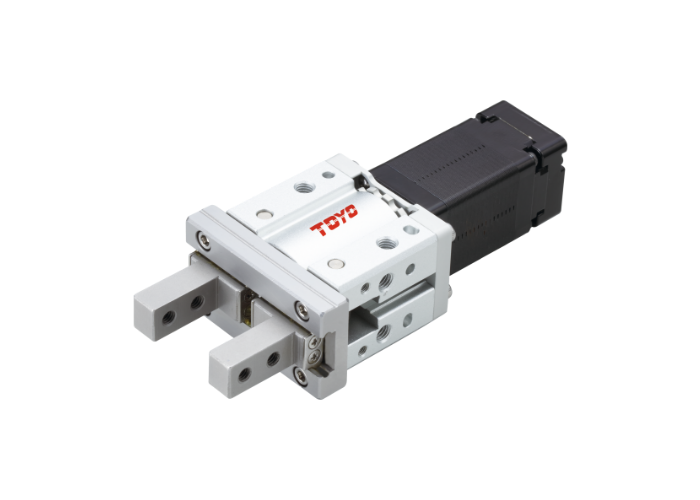

Also known as a servo-electric gripper, an electric gripper uses an electric motor to control the fingers of the gripper. Electric grippers are a popular choice for many collaborative robot applications, including machine tending and pick-and-place operations. Electric grippers typically come in two-jaw and three-jaw configurations. When it is necessary to handle round/cylindrical objects such as cans or bottles, three-jaw grippers are usually the preferred option.

A defining feature of electric grippers is precise control. Most electric grippers are equipped with a microprocessor that allows you to adjust the gripping force and speed. Additionally, the added force sensors enable electric grippers to understand the force required for each task, helping them easily handle different types of parts.